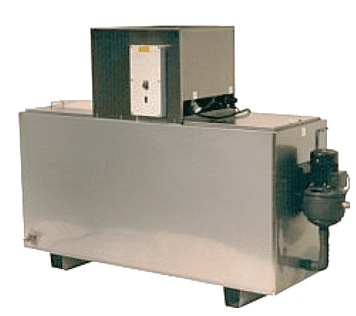

tub pasteurizers

The WP series tank pasteurizers are type-tested and designed as pressureless stainless steel tanks. These are ideal for the production of cheese, cream cheese, quark and yoghurt, etc. Pasteurization must be carried out within a narrow tolerance range of the processing temperature - both with maximum and minimum filling. The required temperature of 63.5°C must not deviate by more than 1.5°C up or down and must be kept constant over a period of 32 minutes. The automatic pasteurization process is recorded and documented using a digital temperature recorder. An acoustic signal informs the operator that the process has been completed successfully or that there are any irregularities. The high-quality containers are available from 50 l to 450 l.

• Container made of stainless steel 1.4301

• 3-wall insulated container with base

• Cover made of stainless steel 1.4301

• Sensor sits in the milk, sensor opening 48 mm

• Lid with filling opening and puncture lid PVC

• Lid optionally without filling hole

• Agitator firmly mounted on the cover. Speed approx. 21 rpm

• Thermostatically controlled heating with stop at:

⇒ Opening of the cover

⇒ Opening of the butterfly valve

⇒ Temperature overshoot or undershoot

⇒ afterwards Restart of the pasteurization process

• Outlet straight disc valve WP 50 and WP 100 NW 50 / 2"

• Outlet straight disc valve WP 200 to WP 450 NW 65 / 2.5"

• Control box with electronic 3-program controller and low-level signal horn

• Wall-mount control box

• Program 1: Pasteurizing program is pre-programmed

• Program 2 and 3 : Can be programmed on customer request.

• Digital temperature recorder

• Electromotive ball valve

• Water inlet WP 50 – WP 450 : ½"

• Water outlet WP 50 – WP 300 : ¾"

HP 450: 1"

• The system may only be operated without pressure

• The container contents of the three-walled container pasteuriser are heated via a pressureless water jacket and automatically cooled with cold water after the holding time has elapsed (single-circuit system)

• Operating voltage: 3 x 400V/N/PE-50Hz

The pasteurizers of the WPD series are pressure-resistant without integrated heating. This makes it possible to pump hot water with the optionally available separate heating system and ice-cold water with the optionally available ice water maker through the surfaces in the floor and side walls designed as heat exchangers. The time frame prescribed for drinking milk pasteurization is adhered to. All pasteurizers have a 3-program controller in which the pasteurizer program is pre-programmed. Two other programs can be set on request. The ETSCHEID tub pasteurizers can be purchased in the versions 200 l, 300 l and 450 l.

• 3-walled, insulated container made of stainless steel 1.4301

• With base

• Bottom and side walls designed as heat exchangers

• Cover made of stainless steel 1.4301

• Sensor sits in the milk, sensor opening 48 mm

• Lid without filling opening, without pierced lid

• Agitator firmly mounted on the lid. Speed approx. 21 rpm

• Outlet straight disc valve NW 65 / 2.5"

• Restart of the pasteurization process at:

⇒ Opening of the cover

⇒ Opening of the straight disc valve

⇒ Exceeding or falling below the temperature

⇒ afterwards Restart of the pasteurization process

• Control box with electronic 3-program controller and low-level signal horn

• Wall-mount control box

• Program 1 : Pasteurizing program is pre-programmed

• Program 2 and 3 : Can be programmed on customer request

• Digital temperature recorder

• Water inlet-outlet for heating-cooling with :

4 x solenoid valves 1"

2 x solenoid valves ¾" for pre-cooling with

city water

3 x check valves 1"

• The system is suitable for the production of drinking milk

• Please coordinate the exact design with the responsible official engineer

• Operating voltage: 3 x 400V/N/PE-50Hz

| Inhalt (ltr.) | Abmessungen Außen-Innen (mm) | Artikel Nr. | Fußgestell (mm) | Füllmenge Min./ Max. (ltr.) | Heizung (kW) |

|---|---|---|---|---|---|

| 50 | 625 – 548 | 603 025 | 400 | 25 / 50 | 1 x 3,0 |

| 12,13 A | |||||

| 100 | 780 - 710 | 603 026 | 400 | 48 / 100 | 1 x 8,4 |

| 12,13 A | |||||

| 200 | 880 – 800 | 603 027 | 400 | 60 / 200 | 2 x 8,4 |

| 24,26 A | |||||

| 300 | 880 – 800 | 603 028 | 400 | 60 / 300 | 2 x 8,4 |

| 24,26 A | |||||

| 450 | 1160 - 1085 | 603 029 | 400 | 115 / 450 | 2 x 8,4 |

| 24,26 A |

• Insulated tank 250 l, with built-in heating elements

For WPD 200 – 3kW + 12kW

For WPD 300 – 3kW + 18kW

For WPD 450 – 3kW + 24kW

(to generate a water reserve of 96°C hot water)

• Condensate overflow NW 40

• Pump, stainless steel

• Control box

• EWB ice water maker

• To build up an ice supply for 1 pasteurization process / day

• Water basin, insulated, stainless steel

• Pump, stainless steel

• Basin EWB 200 – 590 l

• Basin EWB 300 – 730 l

• Basin EWB 450 – 880 l